Skip to content

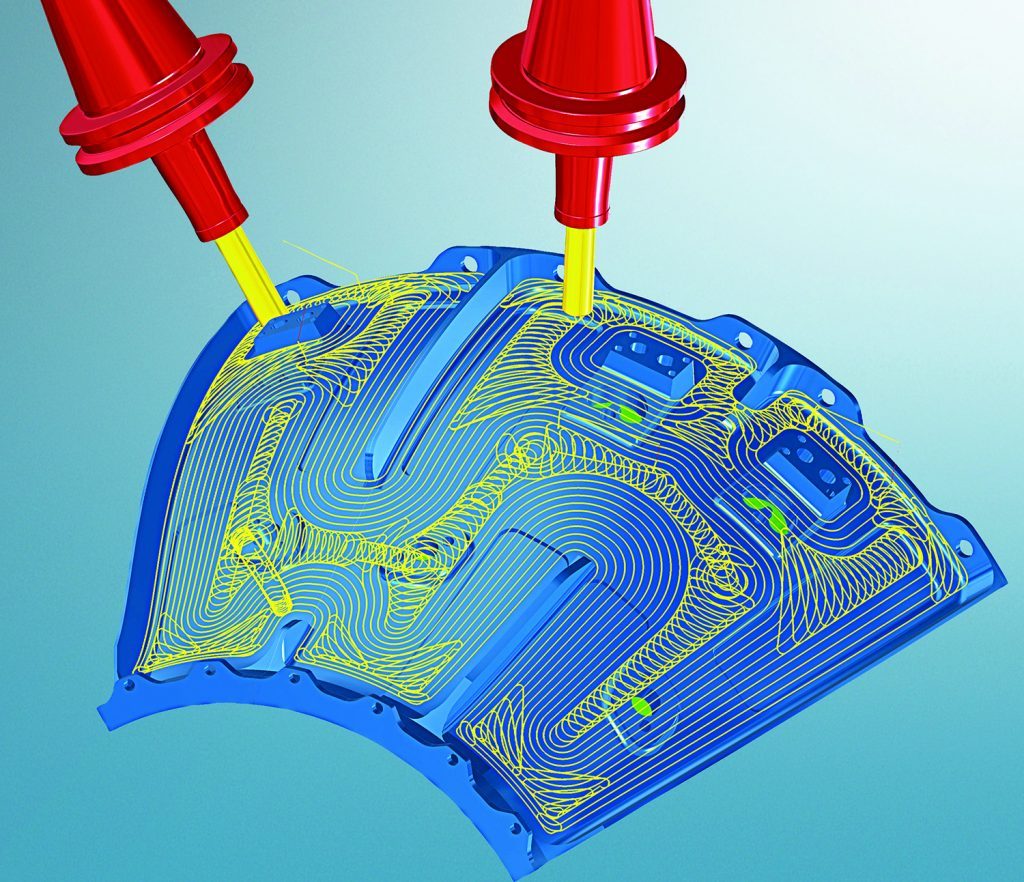

Manufacturing Capabilities

- 3, 4, and 5 Axis CNC Milling

- Live Tool CNC Turning from .010 to 8.0in Diameter

- Micro Machining

- Tool Room Grinding

- Micro Drilling

- Electrical Discharge Machining (EDM) – Wire

- Kiting and Assembly

- Part Marking

- Functional Testing

- AS9100D Quality Assurance

Project Examples

- Specialty Instruments and Prototype Devices

- Medical Devices and Surgical Instruments

- Photonics and Laser Science Hardware

- Laboratory and Experimentation Hardware

- Space Flight and Propulsion Components

- Instrumentation Chassis and Components

- Electronics enclosures, carts, and rack mount instruments

Systems Capabilities

- Custom Bench Instruments

- Custom Process Machines

- SCADA and Data Acquisition Systems

- Test Cell Subsystems

We Design in SolidWorks 2024

- Solid Modeling

- ASME & ISO Standards

- CAE using SolidWorks Cosmos

- Tolerance Design

- Design for Manufacturing

- Design for Maintenance

- Patent Drafting

- Design Review

error: Content is protected !!